Liujing Technology Group has the most complete industrial chain in the field of waste sand recycling in China, and its environmental protection high-end equipment manufacturing section is in a leading position in China.

The technical equipment developed and produced by Liujing Technology Group is suitable for the comprehensive recycling of waste sand in the foundry industry and the harmless treatment of foundry waste. Its fully automatic casting waste sand recycling equipment complete system, fully automatic coated sand equipment complete system, in intelligent control, stable operation, technical indicators and other aspects of the unique, from materials to finished products fully automatic production completed, can completely improve the current industry semi-automated production status, for customers to save labor costs, improve the working environment, improve production efficiency. Equipped with environmentally friendly sand adding device, multi-directional airflow driving device, combustion energy-saving design, so that Liujing recycling equipment more in line with national environmental protection requirements.

Equipment features

● The built-in countercurrent heat exchanger can efficiently recover waste heat, with remarkable energy saving effect, low fuel consumption and low regeneration cost.

The secondary roasting method is adopted, and the quality of reclaimed sand is excellent and uniform.

Low temperature roasting greatly reduces the damage of the furnace and air nozzle, and the roasting furnace does not need maintenance.

Low exhaust emissions, low temperature, dust waste heat recovery device can be miniaturized, saving investment costs and land.

● The full set of automation equipment adopts PLC control system, and the control panel is fully automated touch man-machine interface; the operation is simple and convenient, and the manpower saving can ensure the stability of production efficiency and product quality.

● A full set of automation equipment can be equipped with MES system to collect and store data; Traceability and query can be realized in the process of waste sand disposal.

● Can be used for waste heat regeneration.

Main product technical indicators

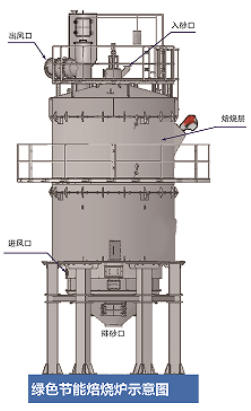

Green energy-saving baking furnace

| Project \Model Name | 2 ton roasting furnace | 3 ton roasting furnace | 5 ton roasting furnace | Product Picture |

| Processing capacity of roasting furnace | 2 tons/hour | 3 tons/hour | 5 tons/hour |  |

| Roasting furnace body height | About 10m1 | Approximately 11m. | Approximately 11m. | |

| Outer diameter of roasting furnace body | 2.9m | 3.1m | 3.9m | |

| system control method | PLC touch panel | PLC touch panel | PLC touch panel | |

| Use of fuel | Natural gas | Natural gas | Natural gas | |

| Heating mode | Burner | Burner | Burner |

Technical and economic indicators of recycled sand

| Project | Parameters |

| regeneration rate | 75-85% when 100 clay sand, more than 95% when 100 shell core sand |

| Average energy consumption | 8-15 cube/ton sand; 5-200000 kcal/ton sand |

| Regeneration costs | 150 yuan -200 yuan/ton sand(case) |

PLC control system

The control panel is a fully automated touch man-machine interface, which is simple and convenient to operate and saves manpower to ensure the stability of production efficiency and product quality.

| Project \Model Name | 350KG Mixer | 500KG Mixer | Product Picture | Picture of PLC control system |

| Exterior dimension | Φ1584 X h4780 | Φ1884 X h5000 |  |

|

| effective capacity | 350KG | 500KG | ||

| Processing capacity | About 7 tons/hour | About 10 tons/hour | ||

| system control method | PLC touch panel | PLC touch panel | ||

| Working high-pressure air pressure | 0.5~0.8Mpa | 0.5~0.8Mpa | ||

| Equipment weight | Approximately 6.5 tons | about 8 tons. |

Coated sand production line system

The production line system adopts batch production mode, 500kg/batch, and the production capacity is> 10t/Hr (coated sand output).

| Serial Number | Project | basic condition parameters | Product Picture |

| 1 | Production capacity | 7-12T/hr |  |

| 2 | strength of coated sand | 30-150kg/cm2 | |

| 3 | Finished sand temperature | ≤ 50 ℃ | |

| 4 | Coated sand energy consumption | Below 4.5L/t |

Previous Page

Next Page