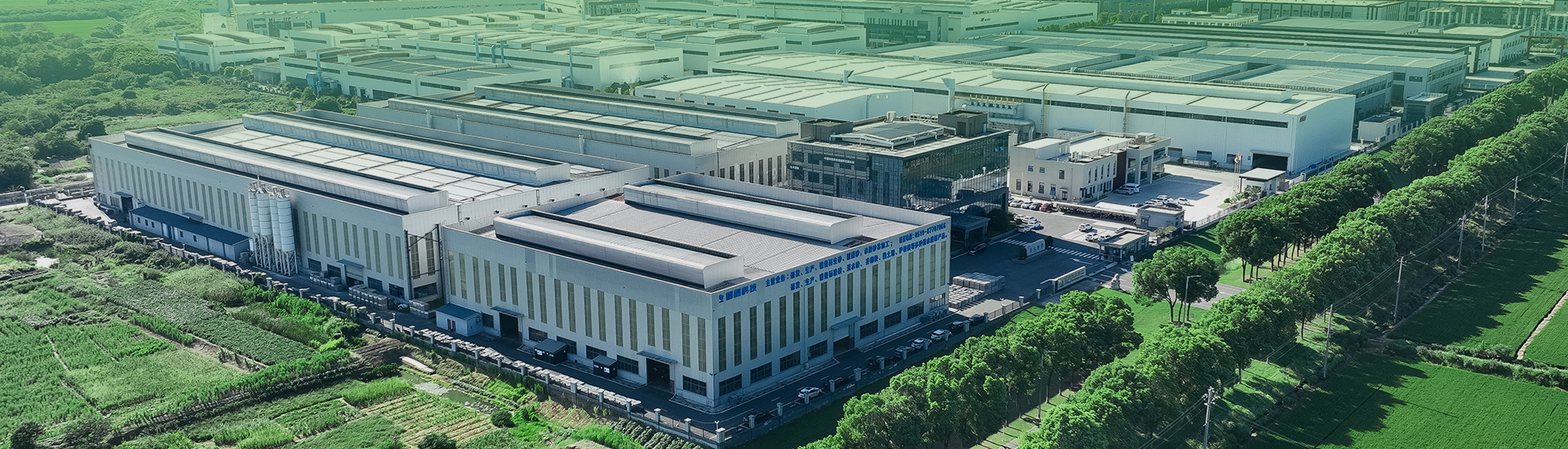

Enterprise Base

Liuzhou Base

We have one production line with an annual output of 50000 tons of refractory coatings.

Two fully automatic production lines with an annual output of 100000 tons of laminated sand.

Two fully automatic organic recycled sand production lines with an annual output of 150000 tons.

Liyang Base

We have 4 fully automatic organic recycled sand production lines with an annual output of 50000 tons.

One fully automatic inorganic regenerated sand production line with an annual output of 50000 tons.

Two fully automatic production lines with an annual output of 100000 tons of laminated sand.

One production line with an annual output of 50000 tons of non sintered Ceramsite particles.

One production line with an annual output of 300000 square meters of Ceramsite permeable building materials.

One factory with an annual production capacity of 10 sets of recycled sand, laminated sand, and complete equipment manufacturing.

Changchun Base

Anhui Base

Four fully automatic organic recycled sand production lines with an annual output of 50000 tons are planned to be built.

Two fully automatic film coated sand production lines with an annual output of 100000 tons are planned to be built.

Weifang in Shandong and other bases are under preparation for construction

......

International Cooperation

As a demonstration base for the recycling of solid casting waste in China, Liujing Technology has demonstrated its advantages in online management and recycling of casting waste, as well as research and development, production, and sales of coated sand.

Faced with the reality that inorganic casting waste sand cannot be processed domestically, Liujing Technology has cooperated with German RS and BSSW companies to introduce advanced German technology and equipment, becoming the "first person to eat the crab" in China's inorganic waste sand treatment. This has taken China's casting industry to a new level of resource regeneration and green development, and opened up a scientific, effective, and internationally cooperative new path for building a circular economy and environmentally friendly society.

By introducing advanced technology and equipment from Germany, Liujing Technology has become a pioneer in the treatment of inorganic waste sand in China, opening up a new path for resource regeneration and green development of China's foundry industry. This international cooperation not only enhances the technological level of Liujing Technology, but also contributes to the sustainable development of China's foundry industry.