Liujing Technology Group casting waste comprehensive utilization of technology and equipment into the national industrial resources comprehensive utilization of advanced and applicable technology and equipment catalogue

Release time:

2023-07-31

Equipment name: casting waste comprehensive utilisation technology and equipment

1. Scope of application

Scope of application: Comprehensive utilisation of foundry waste sand.

2. Technical principle and process

The equipment utilises the organic components in the foundry clay waste sand as the main fuel for roasting, adopts precise temperature control technology to make the sand grains heated uniformly, ensuring the full decomposition of the organic components and uniform phase change of the sand grains, and then under the action of the wind, make the sand grains in the boiling state of mechanical grinding, and the clay on the surface of the sand grains is mechanically grinded and stripped off, and taken away by the wind pressure, so as to obtain the regenerated sand with the performance superior to that of the original new sand, which is used for the production of foundry sand moulds, realising the principle of comprehensive utilisation of foundry waste sand. The regenerated sand is then used for casting sand production, realising the recycling of casting clay waste sand.

The process flow is as follows: foundry organic waste sand → primary crushing → primary magnetic separation → secondary crushing → secondary magnetic separation → high temperature roasting → cooling → mechanical grinding → wind to remove dust → sieving → recycled sand.

3. Technical indicators

(1) Key technologies: rapid grinding device technology for inorganic binder waste sand; waste sand crushing device technology; waste sand baking and grinding device technology; waste sand filtering and recycling device technology.

(2) Main technical indicators: production capacity of >5t/h, finished sand temperature <35 ℃, recovery rate of 90%, scorch reduction of ≤ 0.2%, mud content of ≤ 0.3%; high temperature air pressure of 0.4-0.7MPa, gas consumption of 13m ³ / t, PH <8, average energy consumption of 50,000-200,000 kcal / ton of sand, the rate of regeneration: 75%-85% of the time when the 100% clay sand, 100% of shells More than 95% for sand core.

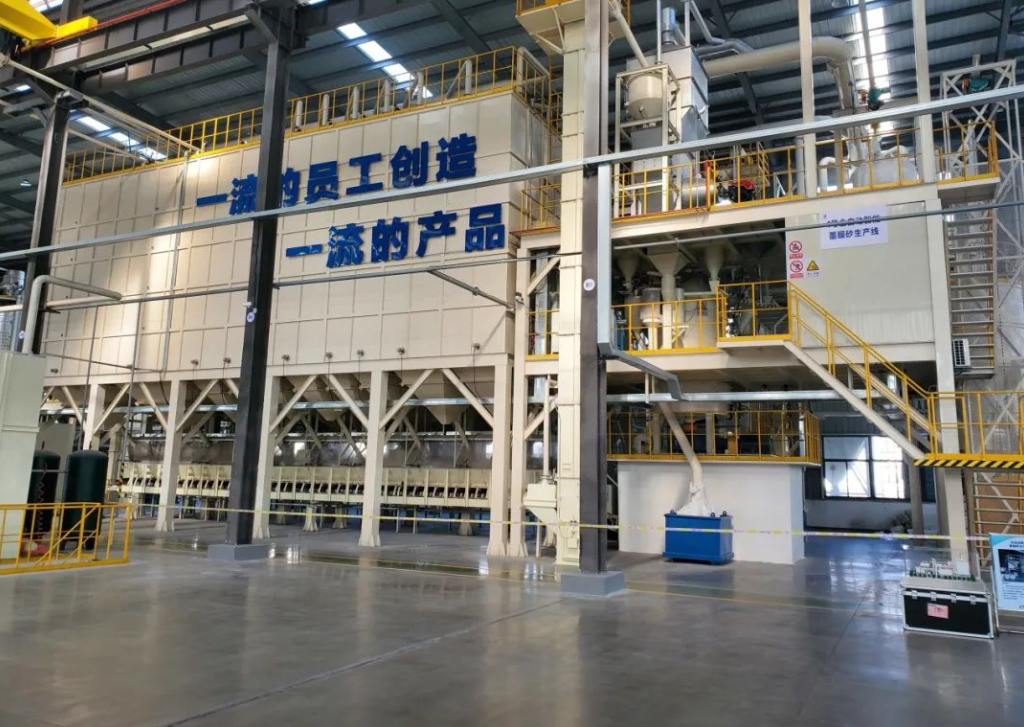

Full-automatic regeneration of foundry waste sand complete sets of technical equipment

Casting waste sand equipment

4. Technical features

(1) Adopting closed automatic sand adding device, the waste sand enters into the roaster directly through the sand adding device, and when discharging, the computer automatically controls the discharging valve to realise intermittent cyclic discharging.

(2) Adopt the design of heat preservation system of the roaster, the design of the furnace lining adopts advanced refractory materials and heat preservation and insulation technology, so as to reduce the temperature of the exterior of the furnace body.

(3) Adopt sand level automatic control system, automatically switch off the fire when the sand level in the furnace is at the set low level, and stop charging when the sand level in the furnace is at the set high level.

(4) the use of high-temperature sand cooling system, hot sand in suspension with the heat exchange is not visible contact and heat transfer cooling, in the process of sand particles in the movement of the rubbing effect between the adhering micro-division of detachment and with the airflow into the dust removal system.

(5) Adopt surface treatment device, low force cutting machine can realise continuous force cutting, remove 0.01mm alkaline substance on the surface of sand and separate the surface dust.

(6) Intelligent design: establish a data model, based on the roasting temperature, the system automatically adjusts the process parameters according to the temperature, the amplitude and frequency of temperature fluctuation and the fluctuation speed. Build MES system to regulate the feeding, process and parameters of the production process.

5. Application cases

The technology of this project is independently developed and provided by our company, which is applied in Xixia Zhongde Automobile Parts Co., Ltd, including 2 sets of intelligent and fully automatic casting waste sand regeneration equipment sets and 1 set of intelligent and fully automatic coating sand equipment sets. In the service project of comprehensive utilisation of foundry solid waste of Liujing (Liyang) Environmental Protection Technology Co., Ltd, the company provides supporting equipment and systems, including intelligent fully-automatic laminating sand equipment sets, foundry waste sand regeneration equipment sets, Phase I and Phase II, etc.

6.Future Promotion Prospects

The reuse rate of casting waste sand in China is relatively low, and most of the waste sand is mainly discarded and landfilled. This technology is focused on promoting the comprehensive utilisation of casting waste, and has certain promotion prospects.

Company Profile:

Established in August 2018, Liujing Machinery Equipment (Liyang) Co., Ltd. is a wholly-owned subsidiary of Liujing Technology Group Co., Ltd. and is a science and technology enterprise specialising in complete sets of equipment for casting sand production such as film-coated sand and regenerated sand, located in Zhuluding Town, Liyang City, Jiangsu Province (the first ‘China Green Foundry Town’ in the country), covering an area of 28,800 square metres. It covers an area of 28,800 square metres. The company's legal representative Ren Wenqiang, founder of Liu Jing Technology Group, chairman of the board of directors, is a graduate student of the University of Hong Kong, with 20 years of experience in the foundry and related industries, began to establish the Liu Jing Technology in 2012 and the introduction of machinery and equipment production and research base, is committed to the international advanced casting technology to achieve local production and production equipment in the production of a huge investment in scientific research efforts. The general manager of the company, Liao Chaozong, has more than 40 years of experience in research and development, production and management in the foundry industry, and has participated in a number of research and development and improvement projects for the production equipment of coated sand and recycled sand. The company's R & D design and production of technology and equipment products are suitable for comprehensive recycling of waste sand produced in the foundry industry, casting waste harmless treatment, is a kind of resource recycling equipment. The development of the equipment can improve the current semi-automated production status in the industry, from material to finished product fully automated production is completed, for customers to save manpower costs, improve the working environment, and effectively enhance production efficiency. At the same time, it is set with environmentally friendly sanding device, multi-directional airflow push device, and energy-saving design of combustion, which makes the product more in line with the national environmental protection requirements.

More News